How can you quickly generate high-quality imaging during NDT inspections of thick parts?

In the field of non-destructive testing, the challenge of rapid and accurate inspection of thick parts remains a constant preoccupation. The need for timely, high quality imaging is paramount to ensuring the integrity and safety of various industrial components. To meet this challenge, our innovative solution combines our CP300DS with our Go-Scan detectors, promising fast and accurate inspections of even the thickest materials.

Through a compelling case study, we illustrate how this synergy produces outstanding results, providing an insight into the effectiveness and efficiency of our integrated approach to NDT inspections.

Case study:

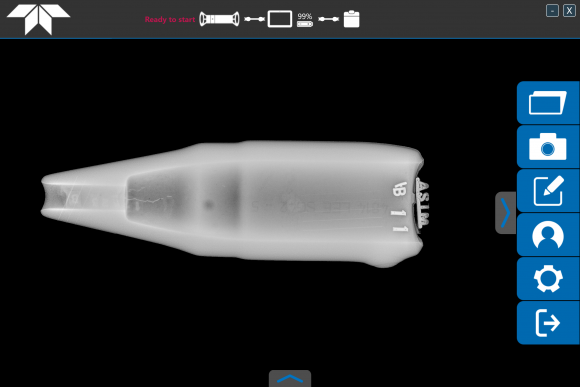

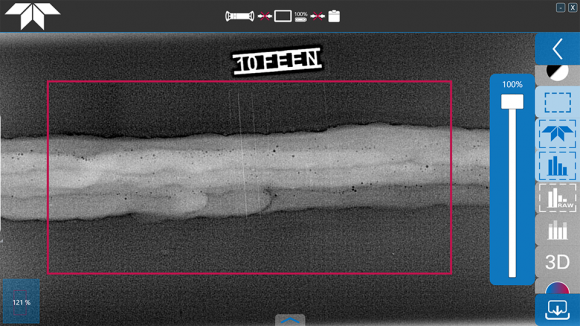

We had to inspect a mortar shell with a steel thickness of +/- 25 mm and a steel plate 20 mm thick.

For both inspections, we use our CP300DS (1 mm focal spot) and our Go-Scan 4335 (active area: 43 x 35 cm).

Set-up for the mortar shell:

- 290 kV

- 3,1 mA

- 3,5 sec integration time

- 4 frames

Image generated:

We obtained our high-quality image in less than 15 seconds.

Set-up for the steel plate:

- 270 kV

- 3,3 mA

- 4 sec integration time

- 4 frames

Image generated:

We obtained our high-quality image in less than 20 seconds.

Conclusion:

In conclusion, the combination of our CP300DS and Go-Scan 4335 offers a fast and effective solution for generating high-quality images during NDT inspections of thick parts. The case study illustrates this, with successful inspections of a mortar shell and a steel plate, both over 20 mm thick. With optimized parameters tailored to each material, including variations in kV, mA, integration time and frames, we achieved excellent results in less than 20 seconds. This integrated system not only ensures fast inspections, but also preserves the integrity of the imaging, making it an invaluable asset for NDT professionals looking for fast but reliable analysis of thick parts.

Interested to discover our digital radiography solutions for NDT inspection?