1. Introduction

This presentation is designed to demonstrate the image quality two different types of x-ray technology can offer, being Constant Potential (CP) and Pulsed generators, based on the magnification technique.

For this test, we have used the Teledyne LITEX and the Golden Engineering XR150, both batteries powered along with the Teledyne TactX detector.

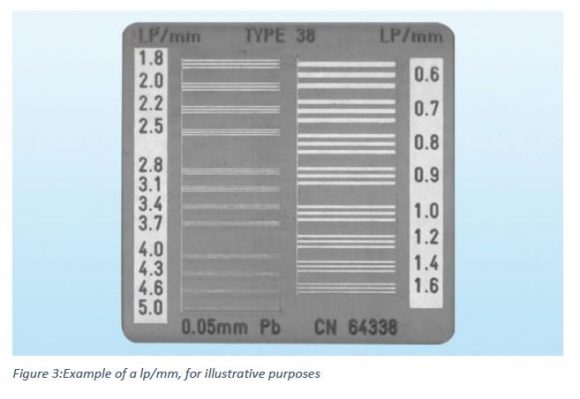

The test will consist of placing measurement tools (LP/mm) at different distances from the detector and determining which lines are still visible. Using this technique, we will see that the focal spot dimensions will have a considerable impact on the image quality.

2. Theoretical reminders

a. Constant Potential vs Pulsed technology

- CP sources:

For CP sources, DC voltage is applied to the tube. The electron emission is based on the thermo-ionic emission: a tungsten filament is heated up by the Joule effect like in a classical bulb.

The high-frequency regulation allows having a very stable and repeatable X-ray dose. Moreover, the output tube voltage and current are completely selectable.

Due to the good thermal capacity, the constant potential X-ray source can work for 25 minutes at full power.

- Pulsed sources:

For pulsed sources, repetitive high voltage pulses are applied to the tube. The very high flow of electrons is emitted from a pin by explosive emission effect.

As the instantaneous current is very high, the pin is progressively degraded. During its lifetime, as the pin shape is modified, the dose rate is evolving. The repeatability of the dose is then limited.

The X-ray emission time is very limited: only few seconds (each pulse is around 50 ns long). Also, the voltage applied on the tube is not selectable. Only 300 pulses can be performed before waiting for cooling down, i.e. less than 5 seconds of X-ray exposure

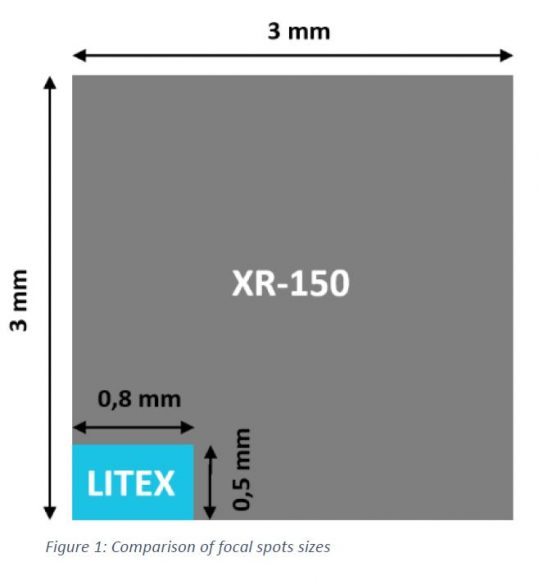

b. Focal spot

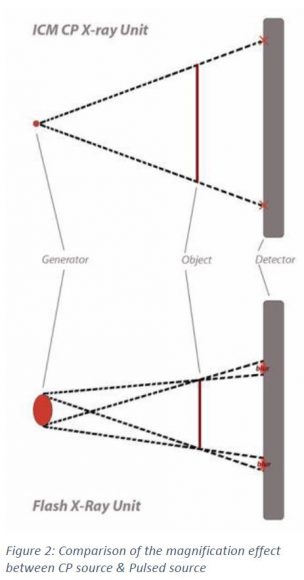

The Teledyne ICM LITEX source features very small focal spots of 0.8 x 0.5mm. The Golden Engineering X-Ray sources possess a focal spot of 3.0 x 3.0mm. The size of the focal spot will impact the radiography, no matter the resolution of the detector. A large focal spot will inevitably cause a blurred image when doing magnification. Please refer to the following sketch for better understanding.

c. Magnification

The technique of magnification consists on placing the object to be inspected away from the detector to see greater details by, magnification. This is when focal spot matters most as the smaller focal spot we have, the better image quality we will be able to have.

3. Technical specifications of equipment used

- Generators

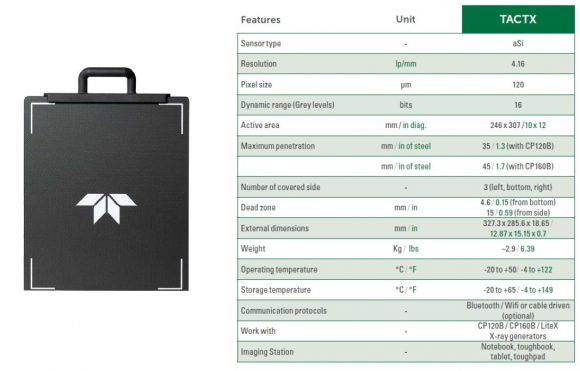

- Detectors

4. Magnification test:

For the test we have used a Lead Test objects (LP/mm tool) CNB2688 type 38. This will allow us to determine which line are still visible.

5. Magnification test:

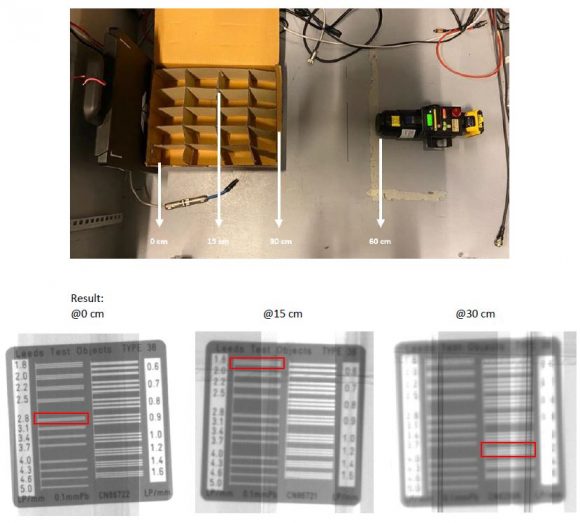

• Test 1:

We have used 3x the same LP/mm placed in a box at 3 different distances, being 0mm, 150mm and 300mm from the detector. The first test performed was with the golden engineering XR-150 giving 30 pulses to allow enough time to start the Teledyne TactX detector to acquire an image. The Teledyne software Sherlock NDT has not synchronized Golden Engineering equipment, therefor we have been using it in manual mode.

- Test2:

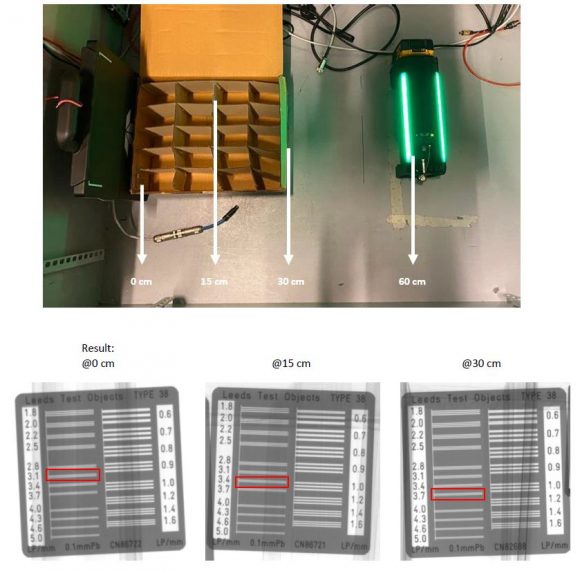

Now let’s see what result we can have when using the Teledyne LITEX with a 0.7 x 0.5mm focal spot using the exact same set up and an exposure of 1sec @ 120kV, 0.25mA.

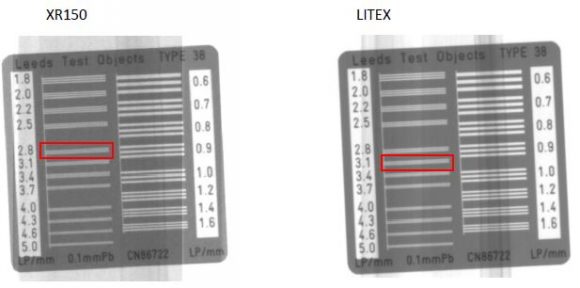

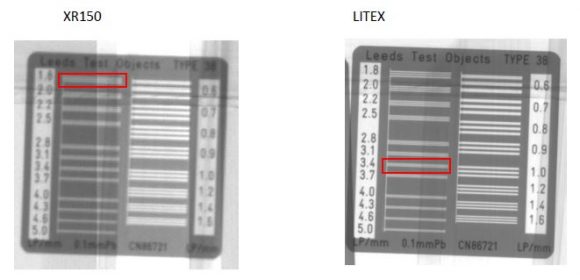

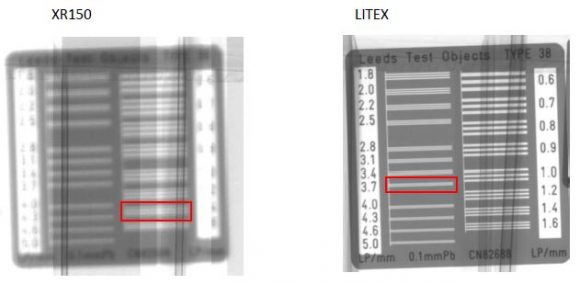

- 6. Comparison images XR150 (Pulsed) vs LITEX (Constant Potential)

•@ 0cm: the Litex with its small focal spot offers already a better resolution with being to see 3.1lp/mm vs 2.8lp/mm for the XR150.

- @ 15cm: the Litex is again offering a better resolution with being able to see 3.4lp/mm vs hardly 1.8lp/mm for the XR150. This also demonstrate that doing magnification allow us to see greater details with a CP small focal spot when we decrease image quality with a pulsed equipment.

- @ 30cm: Here again the Litex offers a better resolution with being able to see 3.7lp/mm vs hardly 1.4lp/mm for the XR150.

7. Conclusion

These tests demonstrate that the image quality delivered with a Constant Potential generator is already slightly better than a pulsed generator when the object is placed against the detector. But what matters most is when we start doing magnification @15cm or @30cm, we can see the image quality degrades rapidly using a pulsed equipment but increases using a CP. The constant potential technology can deliver such a great image quality, reaching 3.7 LP/mm, thanks to its small focal spot. This cannot be matched with a pulsed equipment type, reaching 1.4 LP/mm, and resulting in a blurry image due to its much larger focal spot for this technique. Doing magnification can be used to increase the size of objects inside a suspect package then offer more visible details which is what can be needed doing an inspection.

ABOUT TELEDYNE ICM

Our mission, at Teledyne ICM, is to facilitate professionals’ life by providing innovative, user-friendly, and safe X-ray solutions, while accompanying them throughout the use of our products.

For almost 30 years, Teledyne ICM has been a worldwide-active company specializing in developing and manufacturing portable x-ray generators and detectors for Non Destructing Testing and security purposes. Today, our x-ray solutions have permitted safe, accurate and easy testing for countless inspections and threat assessments around the globe.

Regardless of your application and budget, we will find the right x-ray product to fit your needs. From pipeline nondestructive testing inspections to military, EOD or counter terror applications … Teledyne ICM will always provide the lightest and most robust portable X-Ray solutions out there.

[This article was originally published in the Fall edition of Counter-IED Report 2022 – find it here: https://issuu.com/deltabusinessmedialimited/docs/counter-ied_report_autumn_2022?fr=sZDI1OTQ1MDA3NQ]